Understanding Valves in Truck Spare Parts A Comprehensive Guide

In the world of truck spare parts, valves play a crucial role in ensuring optimal performance, safety, and efficiency. As a leading manufacturer and supplier of truck spare parts, we specialize in providing high-quality valves that meet the diverse needs of the trucking industry. This article delves into the significance of valves, their types, functions, and why choosing the right valve for your truck is essential.

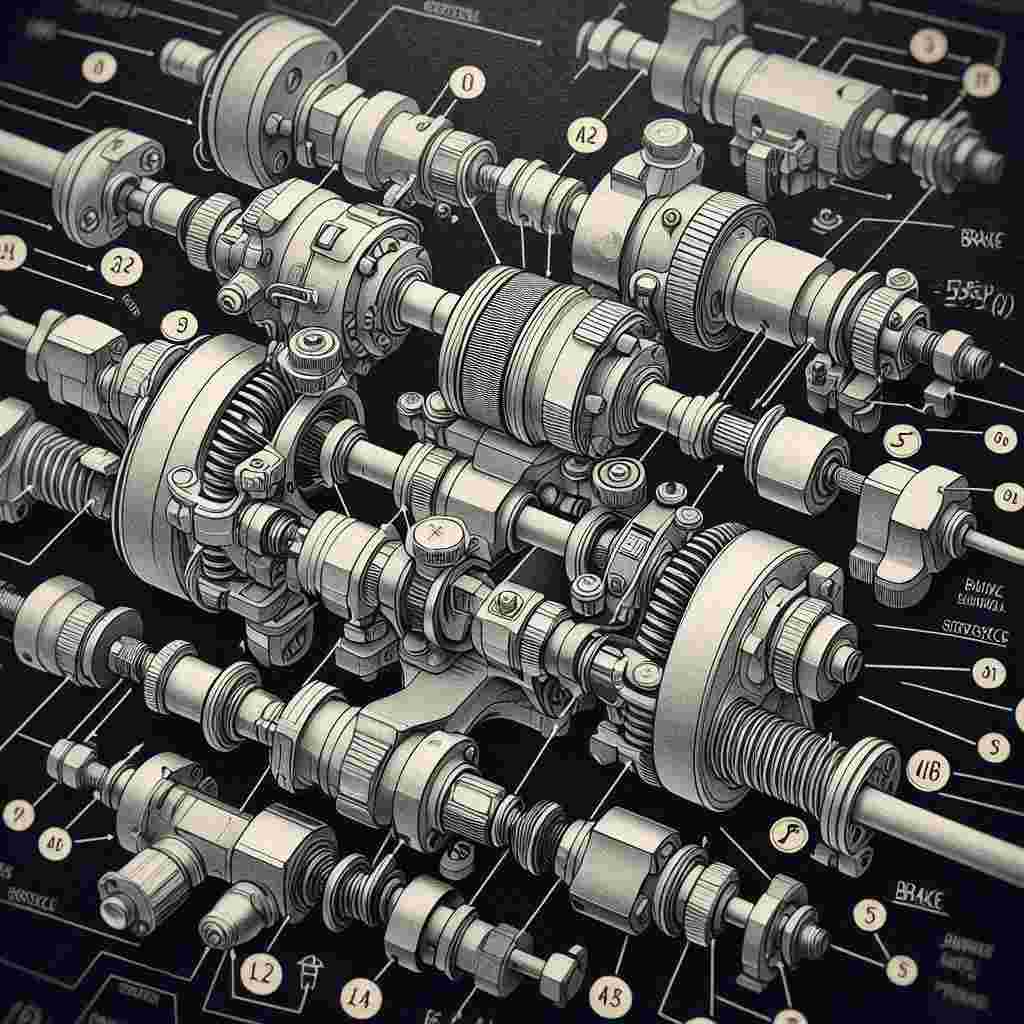

What Are Valves?

Valves are mechanical devices that regulate, direct, or control the flow of fluids (liquids and gases) within a system. In trucks, they are vital components in various systems, including the engine, fuel system, and braking system. By controlling the flow of fluids, valves help maintain the proper pressure and temperature within the truck’s various systems, ensuring efficient operation.

Types of Valves in Truck Spare Parts

1. Height Leveling Control Valves

One of the key types of valves used in trucks is the height leveling control valve. This valve regulates the air suspension system, allowing for adjustments to the truck’s ride height based on load and road conditions. Proper functioning of height leveling control valves is crucial for maintaining stability, comfort, and safety during operation.

2. Fuel Valves

Fuel valves control the flow of fuel from the tank to the engine. They ensure that the engine receives the right amount of fuel at the right time. A malfunctioning fuel valve can lead to poor engine performance, increased fuel consumption, and potential damage to the engine.

3. Oil Pressure Relief Valves

These valves are essential in maintaining optimal oil pressure in the engine. They prevent excessive pressure build-up, which can lead to oil leaks or engine damage. Regular maintenance and timely replacement of oil pressure relief valves are vital to ensure engine longevity.

4. Braking System Valves

Braking system valves, including anti-lock braking system (ABS) valves, play a critical role in ensuring safety. They help control brake fluid pressure, enabling effective braking performance. Any issues with these valves can result in decreased braking efficiency and compromised safety on the road.

5. Water and Coolant Valves

These valves manage the flow of water or coolant in the engine cooling system. They help regulate engine temperature, preventing overheating and ensuring optimal performance. A malfunctioning water or coolant valve can lead to engine damage and costly repairs.

The Importance of Quality Valves

When it comes to truck spare parts, quality is paramount. Poorly manufactured valves can lead to a host of problems, including decreased efficiency, increased emissions, and costly repairs. Here are some reasons why choosing high-quality valves is essential:

1. Safety

Safety is a top priority in the trucking industry. Faulty valves can lead to catastrophic failures, resulting in accidents, injuries, or even fatalities. Investing in high-quality valves minimizes the risk of malfunction and ensures the safety of drivers and cargo.

2. Performance

Quality valves enhance the overall performance of trucks. They ensure that systems operate smoothly and efficiently, leading to improved fuel economy, reduced emissions, and better handling. Well-functioning valves contribute to the longevity of the engine and other critical components.

3. Reliability

Trucks often operate in demanding conditions, and reliability is crucial. High-quality valves are designed to withstand extreme temperatures, pressures, and vibrations, ensuring consistent performance even in challenging environments.

4. Cost-Effectiveness

While high-quality valves may have a higher upfront cost, they often lead to long-term savings. Reliable valves reduce the frequency of repairs and replacements, resulting in lower maintenance costs over time. Moreover, improved fuel efficiency translates to significant savings in fuel costs.

How to Choose the Right Valves

Selecting the right valves for your truck can be daunting, given the variety of options available. Here are some factors to consider when making your choice:

1. Application

Different types of valves are suited for different applications. Consider the specific requirements of your truck’s systems, such as the engine, fuel system, or braking system. Ensure that the valve you choose is designed for the intended application.

2. Material

The material of the valve significantly impacts its performance and durability. Common materials include brass, stainless steel, and plastic. Choose a material that can withstand the operating conditions of your truck, such as temperature, pressure, and exposure to chemicals.

3. Compatibility

Ensure that the valve is compatible with your truck’s make and model. Consult your truck’s manual or seek advice from a knowledgeable professional to find the right valve for your specific vehicle.

4. Brand Reputation

Opt for valves from reputable manufacturers known for their quality and reliability. Research customer reviews and seek recommendations from industry professionals to identify trustworthy brands.

5. Warranty and Support

A good warranty indicates the manufacturer’s confidence in their product. Look for valves that come with a warranty, and consider the availability of customer support in case you encounter any issues.

Maintenance Tips for Truck Valves

To ensure the longevity and optimal performance of truck valves, regular maintenance is essential. Here are some tips for keeping your valves in top condition:

1. Regular Inspections

Conduct routine inspections of your truck’s valves to identify any signs of wear, corrosion, or leakage. Early detection of issues can prevent costly repairs and ensure safe operation.

2. Cleanliness

Keep the valve area clean and free of debris. Contaminants can hinder the valve’s performance and lead to malfunctions.

3. Lubrication

Ensure that valves are adequately lubricated according to the manufacturer’s recommendations. Proper lubrication reduces friction and wear, prolonging the life of the valve.

4. Timely Replacement

Be proactive about replacing worn or damaged valves. Delaying replacement can lead to more significant issues and higher repair costs.

Valves are indispensable components of trucks, playing a vital role in their operation and safety. As a company specializing in truck spare parts, we understand the importance of providing high-quality valves that meet the diverse needs of our customers. By choosing the right valves and adhering to regular maintenance practices, truck owners can ensure optimal performance, safety, and longevity for their vehicles. Trust us for all your truck valve needs, and experience the difference quality makes in the performance of your truck.

Follow us to get detailed information: Valves

Check out our articles Air Filters