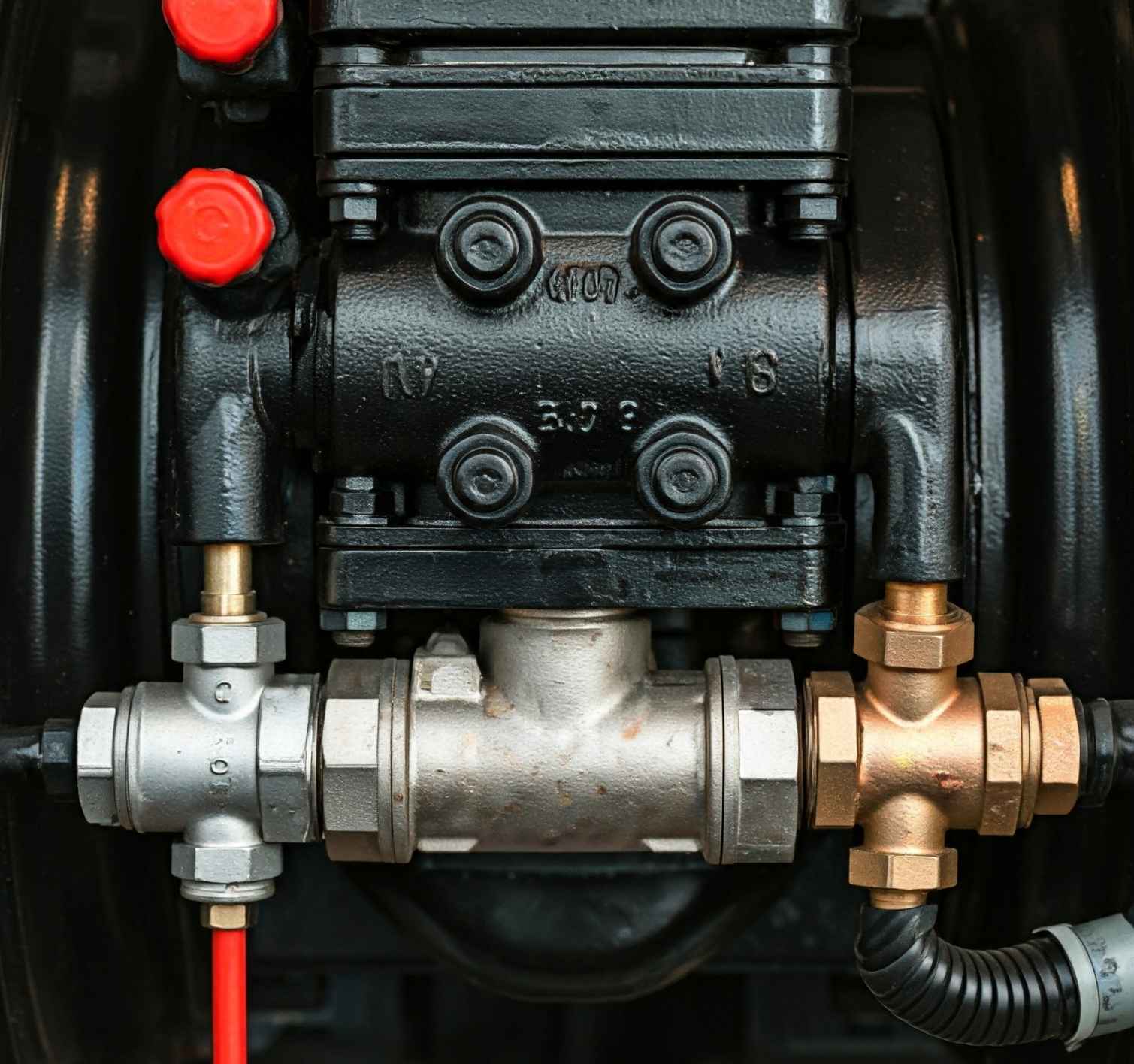

Air brake systems are the lifeline of American trucks, providing reliable stopping power for heavy loads over long distances. Within these systems, valves play a crucial role in controlling air flow and pressure, ensuring optimal braking performance. However, valves can encounter various issues over time, from air leaks to freezing in winter, which may compromise braking efficiency and safety. In this guide, TORQUE PARTS delves into the most common valve issues truck operators face, providing solutions and maintenance tips to keep air brakes functioning at their best.

1. Recognizing Air Leaks in Valves

Issue Overview

Air leaks are among the most prevalent problems in air brake valves. These leaks reduce pressure in the brake system, leading to diminished braking power and, potentially, total brake failure if left unchecked. Leaks can stem from worn seals, cracked valve components, or improper installation.

Signs of Air Leaks

- A noticeable hissing sound near the valves.

- Gradual loss of brake pressure, leading to delayed braking response.

- Frequent compressor cycling as it attempts to compensate for pressure loss.

Troubleshooting and Resolution

- Inspection: Conduct a thorough visual and auditory inspection. Listen for hissing sounds and examine the connections, seals, and components for any visible damage.

- Soap Solution Test: Apply a soap and water solution around the valve and hose connections. Bubbles forming on the surface indicate a leak.

- Replace Seals and Components: Damaged seals or cracked valve components should be replaced immediately. TORQUE PARTS offers durable, high-quality replacement parts specifically designed for American truck air brake systems.

Prevention Tips

Regular inspections are key to preventing leaks. Periodic testing and timely replacement of worn-out seals will help prevent unexpected air leaks and maintain optimal air pressure.

2. Handling Malfunctioning Control Valves

Issue Overview

Control valves are essential for regulating air pressure to each part of the brake system. When these valves malfunction, it can lead to improper air distribution, affecting the truck’s braking performance. Common causes include debris, corrosion, and internal damage.

Signs of Malfunctioning Control Valves

- Uneven or delayed braking.

- Erratic pressure readings on the dashboard.

- Abnormal noises when brakes are applied.

Troubleshooting and Resolution

- Clean the Valve: Over time, dirt, dust, and other debris can clog the valve. Carefully disassemble and clean it, ensuring all particles are removed to restore smooth operation.

- Corrosion Treatment: Use corrosion-resistant lubricants on valve components, or replace corroded parts with high-quality alternatives, such as those from TORQUE PARTS, to enhance valve durability.

- Replace Faulty Control Valves: If the valve remains unresponsive or shows signs of internal damage, replacing it is the safest option. Failing to replace a malfunctioning control valve can result in severe braking issues.

Prevention Tips

Use corrosion-resistant parts and keep a regular maintenance schedule, especially if the truck operates in areas with harsh weather or road conditions that may accelerate wear and corrosion.

3. Dealing with Frozen Valves in Winter

Issue Overview

Frozen valves are a significant concern in winter as the cold temperatures cause moisture within the brake system to freeze. This can obstruct the airflow and lead to sluggish or non-functional brakes, posing severe safety risks.

Signs of Frozen Valves

- Delayed or stiff braking response during winter conditions.

- Frozen or blocked air lines around the valve area.

- Inconsistent air pressure readings due to obstructed airflow.

Troubleshooting and Resolution

- Thawing the Valve: Warm the affected valve gradually using heat packs or a warm cloth. Avoid open flames, as these can damage the valve and surrounding components.

- Use Air Brake Antifreeze: Air brake antifreeze can help prevent freezing in valves and other system components during extreme cold. However, only use products approved for air brakes to avoid system damage.

- Drain Air Tanks Regularly: Regularly draining air tanks helps remove moisture before it freezes. This practice is especially crucial during winter to keep the system moisture-free.

Prevention Tips

Install air dryers and water separators to filter moisture from the system. Periodically check and drain the air tanks to prevent moisture buildup that can lead to frozen valves.

4. Addressing Quick Release Valve Problems

Issue Overview

Quick release valves are designed to expedite the release of air pressure, improving brake response time. If these valves malfunction, braking can become sluggish, affecting overall performance and safety. Issues often arise due to contamination or wear.

Signs of Quick Release Valve Problems

- Delayed brake release after pedal pressure is removed.

- Uneven braking performance.

- Audible hissing even after brakes are released.

Troubleshooting and Resolution

- Clean and Inspect the Valve: Quick release valves can become clogged with debris over time. Carefully clean the valve and check for wear or damage to moving parts.

- Replace Worn Components: Damaged internal components like seals and springs can compromise the quick release function. Replace any worn parts with quality replacements from TORQUE PARTS to ensure reliable performance.

Prevention Tips

Regular cleaning of quick release valves and timely replacement of internal components will ensure efficient brake response. Using filtered air through air dryers helps reduce contamination and extend the life of these valves.

5. Common Issues with Relay Valves

Issue Overview

Relay valves reduce brake lag by enabling faster air distribution to rear brakes. When relay valves malfunction, braking can become unbalanced, increasing the risk of skidding or reduced control.

Signs of Relay Valve Malfunctions

- Rear brakes respond more slowly than front brakes.

- Increased stopping distance.

- Loud air release sounds during braking.

Troubleshooting and Resolution

- Inspect for Air Blockages: Check for obstructions or wear in the relay valve. Clean and clear out any dirt or debris from the valve and air lines to restore smooth airflow.

- Check Valve Adjustment: Some relay valves may require specific adjustments. Ensure all components are aligned and secure according to manufacturer specifications.

- Replace Defective Relay Valves: If adjustment and cleaning don’t resolve the issue, replace the relay valve to restore braking balance and efficiency.

Prevention Tips

Regular inspections of relay valves are essential. Using quality parts from trusted manufacturers like TORQUE PARTS can prevent premature wear and reduce the risk of brake lag.

General Maintenance Tips for Air Brake Valves

1. Schedule Regular Inspections

Routine inspections can catch valve issues early. Regularly check for air leaks, corrosion, and other visible signs of wear.

2. Use High-Quality Replacement Parts

Investing in premium parts can prolong the lifespan of air brake valves. TORQUE PARTS offers a wide range of high-quality valves specifically designed for American trucks, ensuring durability and reliable performance.

3. Keep Valves and Air Lines Clean

Dirt and debris can compromise the efficiency of valves. Clean valve components and air lines to maintain optimal airflow and prevent contamination.

4. Drain the Air System Regularly

Moisture can wreak havoc on air brake components. Draining air tanks and using air dryers helps keep valves and other parts dry, preventing rust, corrosion, and freezing.

5. Educate Drivers on Valve Functionality

Drivers play a key role in identifying valve issues. Training them to recognize the symptoms of common valve problems can lead to quicker detection and resolution, preventing more significant issues down the road.

Valves are integral components of any air brake system, controlling the flow and pressure of air to ensure effective braking. However, like any component, they’re subject to wear and potential malfunctions. By understanding common valve issues such as air leaks, malfunctioning control valves, and frozen valves, truck operators can address problems before they compromise safety. TORQUE PARTS is committed to providing top-quality replacement parts for American trucks, ensuring that our customers’ air brake systems remain safe, efficient, and reliable on every journey. Regular maintenance, timely replacements, and preventive care are the keys to long-lasting and dependable air brake systems.

Follow us to get detailed information: Valves

Check out our Air Brake Components